Optical Assembly Processes: A Breath of Fresh Air for Pristine Precision

Created at : Jun 05 2023

Introduction:

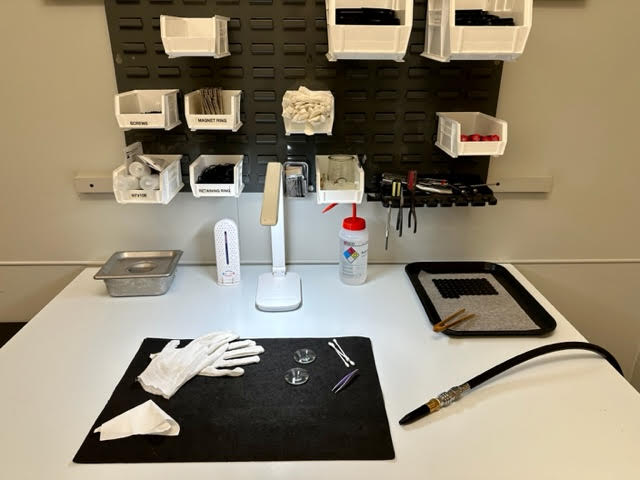

In the world of optical assembly, precision and cleanliness are of paramount importance. Dust particles and dirt can severely compromise the quality and performance of delicate optical components, resulting in diminished clarity, reduced functionality, and potentially costly rework. Recognizing this challenge, Sterling Precision has revolutionized their assembly processes with a groundbreaking solution called New Clear Air Access. By harnessing filtered and humidity-controlled clean air, Sterling Precision ensures the pristine conditions necessary for optimal optical assembly. In this article, we delve into the innovative techniques and advantages provided by Sterling Precision's state-of-the-art clean air access system.

A Revolution in Cleanliness:

Sterling Precision's commitment to excellence is evident in their new Clear Air Access system, which tackles the long-standing challenge of keeping dust particles and dirt away from sensitive optical components during the assembly process. By sourcing clean air from a meticulously filtered and humidity-controlled environment, they have created an assembly station that surpasses industry standards. This breakthrough technology sets a new benchmark for optical precision.

Filtered Air for Uncompromised Quality:

At the heart of Sterling Precision's clean air access system lies an advanced filtration system that removes even the tiniest particles from the air. By employing a combination of high-efficiency particulate air (HEPA) filters and electrostatic precipitators, the system effectively eliminates dust, pollen, and other airborne contaminants. This meticulous filtration ensures that the assembly station remains a sanctuary of cleanliness, enabling precise assembly without the risk of particle interference.

Humidity Control for Optimal Performance:

Humidity, another critical factor in optical assembly, is meticulously controlled in Sterling Precision's clean air access system. Fluctuations in moisture levels can lead to condensation, affecting the integrity of optical surfaces and causing distortions. To combat this, Sterling Precision employs a humidity control system that maintains a constant and optimal level of moisture in the assembly station. This meticulous control minimizes the risk of condensation and ensures consistent, reliable performance from the assembled optical components.

Advantages of Sterling Precision's Clean Air Access:

- Enhanced Product Quality: By minimizing the presence of dust particles and dirt, Sterling Precision's clean air access system enables the production of optical components with superior clarity and functionality. The end result is a product that exceeds customer expectations and sets a new standard for precision.

- Reduced Rework and Wastage: With the clean air access system in place, the risk of contaminants causing defects during the assembly process is significantly reduced. This translates into fewer instances of rework and lower wastage, leading to cost savings and improved overall efficiency.

- Increased Assembly Speed: The pristine environment provided by Sterling Precision's clean air access system allows for streamlined assembly processes. Without the need for constant cleaning and rework, the assembly team can work more efficiently, resulting in faster turnaround times and increased productivity.

- Customer Confidence and Satisfaction: As a result of the meticulous attention to cleanliness and precision, Sterling Precision's clean air access system instills confidence in their customers. Knowing that their optical components are assembled under the most optimal conditions, customers can trust in the reliability and long-term performance of Sterling Precision's products.

Conclusion:

Sterling Precision's new Clear Air Access system is a game-changer in the world of optical assembly. By harnessing filtered and humidity-controlled clean air, they have created an assembly station that ensures the highest level of precision and cleanliness. The elimination of dust particles and dirt, coupled with meticulous humidity control, enhances product quality, reduces rework, increases assembly speed, and instills customer confidence. Sterling Precision's commitment to pushing the boundaries of optical assembly processes sets a new industry standard, where every component is born in a breath of fresh air.

CUSTOM OPTICAL FILTERS

CUSTOM OPTICAL FILTERS

OPTICAL WINDOWS

OPTICAL WINDOWS

OPTICAL COATINGS

OPTICAL COATINGS

UV OPTICS

UV OPTICS

CYLINDRICAL OPTICS

CYLINDRICAL OPTICS

CUSTOM TEMPERED OPTICS

CUSTOM TEMPERED OPTICS

OPTICAL MIRRORS

OPTICAL MIRRORS

NEUTRAL DENSITY

NEUTRAL DENSITY

PRISMS & RETROREFLECTORS

PRISMS & RETROREFLECTORS

ASSEMBLIES

ASSEMBLIES

OPTICAL LENSES

OPTICAL LENSES

NIGHT VISION FILTERS

NIGHT VISION FILTERS

ACHROMATIC LENSES

ACHROMATIC LENSES

OPTICAL BEAM SPLITTERS

OPTICAL BEAM SPLITTERS