Where Our Optics Are Used

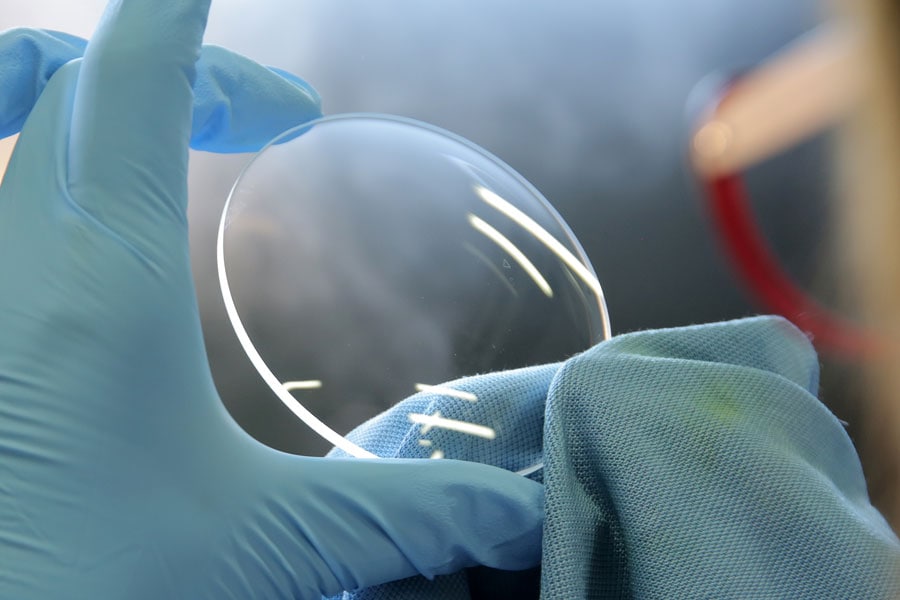

Sterling Precision Optics is a optical manufacturing company serving a diverse array of industries, including aerospace, medical, defense, analytical instruments, detectors, machine vision, underwater photography, and more.

Our optical components are integral to various equipment utilized in aerospace, medical, defense, and scientific fields. For instance, in the medical sector, our custom optical lenses are vital components of medical scopes, and we engineer custom optical filter glass that enhances vein visibility for medical professionals. Additionally, we produce optical filters and custom lenses for blood gas analyzers and other analytical instruments, along with UV filters essential for UV curing systems in the dental industry.

In aerospace, our contributions include crafting gauge covers, anti-reflective covers for instrument panels, and tempered port windows for aircraft taxi lights. Our lenses are also employed in high-altitude cameras onboard aircraft. Furthermore, we fabricate fluid level sight glasses for monitoring fluid levels in aerospace applications.

Within defense applications, we specialize in manufacturing night vision filters for goggles and other equipment, as well as IR windows for fire suppression systems. Moreover, our portfolio encompasses optical lenses, windows, mirrors (both hot and cold), and prism assemblies tailored for fire control systems, M1 tank periscopes, and night vision imaging systems (NVIS).

We provide specialized optical solutions tailored to unique requirements for the scientific industry as well. Our capabilities extend beyond standard components to include solutions like precision lenses optimized for specific medical scopes, advanced optical filters for improved vein detection, and high-performance lenses and optical assemblies for aerospace high-altitude imaging systems. We also collaborate closely with researchers and institutions to deliver specialized optical components for metrology, spectroscopy, and imaging applications, facilitating precise measurement and analysis across diverse disciplines.

Sterling is a full service custom optical and glass company

Custom Products

Select a product type for more

Why Work With Us?

We have been proudly serving the optical community since 1958. We are quick with our response time for R.F.Qs. We are on time with our deliveries. We are quality conscious to your specifications and hold ourselves to our ISO 9001:2015 certification....

ISO 9001:2015 Certified

ISO 9001:2015 Certified

Fabrication and Testing

Fabrication and Testing

Equipment

Equipment

CUSTOM OPTICAL FILTERS

CUSTOM OPTICAL FILTERS

OPTICAL WINDOWS

OPTICAL WINDOWS

OPTICAL COATINGS

OPTICAL COATINGS

UV OPTICS

UV OPTICS

CYLINDRICAL OPTICS

CYLINDRICAL OPTICS

CUSTOM TEMPERED OPTICS

CUSTOM TEMPERED OPTICS

OPTICAL MIRRORS

OPTICAL MIRRORS

NEUTRAL DENSITY

NEUTRAL DENSITY

PRISMS & RETROREFLECTORS

PRISMS & RETROREFLECTORS

ASSEMBLIES

ASSEMBLIES

OPTICAL LENSES

OPTICAL LENSES

NIGHT VISION FILTERS

NIGHT VISION FILTERS

ACHROMATIC LENSES

ACHROMATIC LENSES

OPTICAL BEAM SPLITTERS

OPTICAL BEAM SPLITTERS